In today’s highly competitive logistics landscape, efficiency is king. Technologies such as Dimensioning, Weighing, and Scanning (DWS) systems are essential for streamlining warehouse operations, increasing accuracy, and ensuring regulatory compliance. However, these systems come with their own challenges, particularly when it comes to complying with Canada’s Weights and Measures Act.

According to a 2023 report by Allied Market Research, the global warehouse automation market is projected to reach $57.6 billion by 2031, with DWS systems forming a key part of this growth. Despite their importance, the implementation of DWS systems is fraught with complexities, particularly around regulatory compliance in Canada. This blog explores the critical role of DWS systems, the challenges of complying with the Weights and Measures Act, and why a complete systems integrator is the best choice for managing these complex systems.

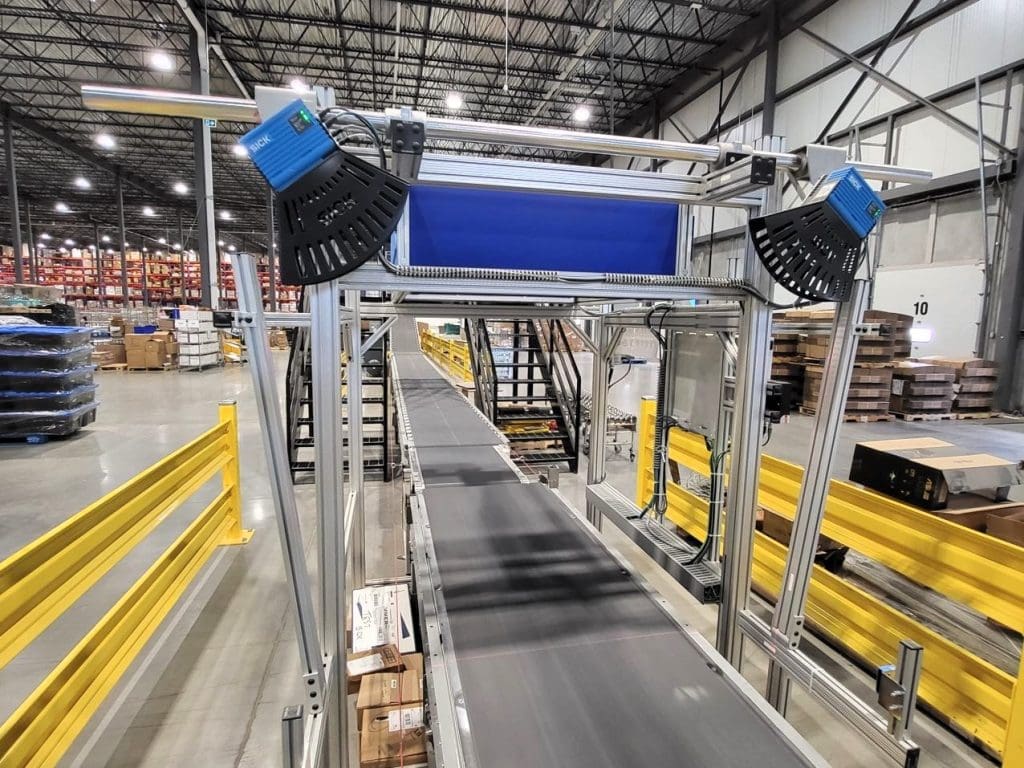

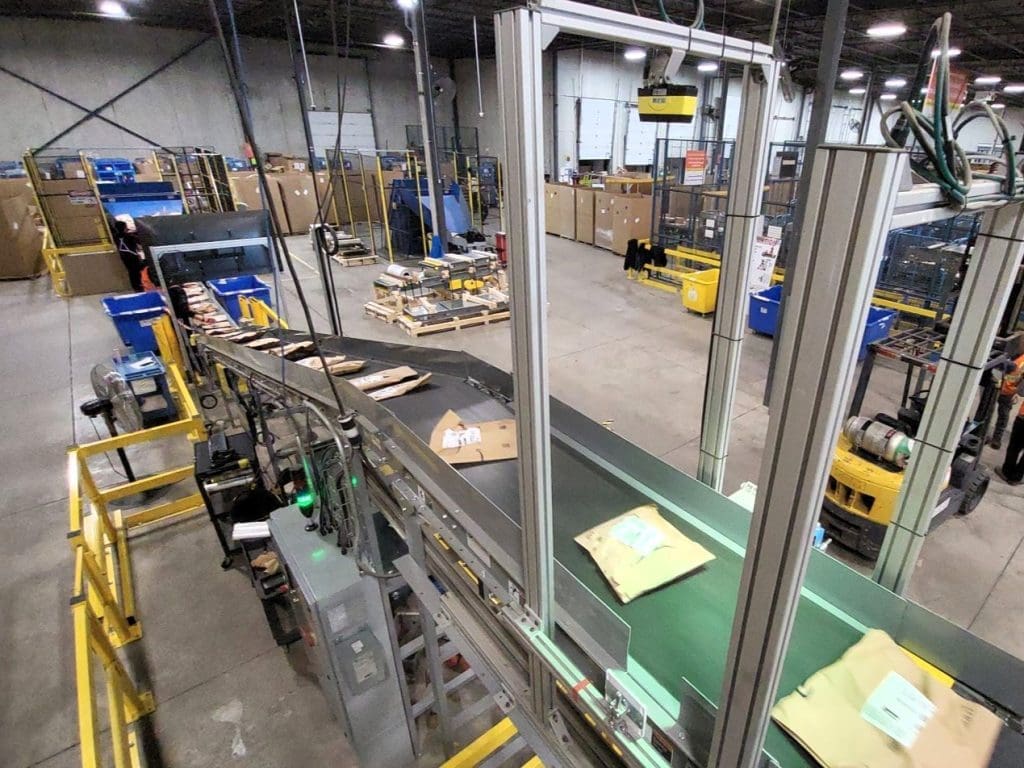

What is Dimensioning, Weighing, and Scanning (DWS)?

DWS systems are essential for capturing data on the size, weight, and barcode information of products moving through the warehouse. Here’s why each of these components is vital for modern warehousing:

Dimensioning: Accurately measuring the dimensions of products and packages is crucial for space optimization, proper shipping costs, and load planning. A 2022 report from Shipware highlighted that dimensional (DIM) weight pricing, a standard used by shipping companies like UPS and FedEx, has become critical for 99% of warehouses, with even a slight miscalculation in dimensions leading to inflated shipping costs and wasted storage space.

Weighing: Weight accuracy is crucial to ensure correct shipping fees and balance loads. According to Pitney Bowes’ 2023 Parcel Shipping Index, incorrect weight entries result in overcharges or losses for 16% of businesses globally, highlighting the need for precise weighing systems. In Canada, any discrepancies in weight measurements can also lead to penalties under the Weights and Measures Act.

Scanning: Scanning technology like barcoding and RFID significantly improves inventory tracking and accuracy. A 2021 study by Zebra Technologies reported that companies using advanced scanning systems saw a 25% improvement in inventory accuracy and a 29% reduction in order errors, which translates to faster order fulfillment and reduced customer complaints.

DID YOU KNOW?

Everyday JUST Temu and SHEIN need 90 planes a day to ship their orders.

Combined for 2,600,000 packages!

Navigating the Weights and Measures Act

In Canada, warehouse operations must comply with the Weights and Measures Act, which enforces the use of accurate measuring devices for commercial transactions. The act is enforced by Measurement Canada, which inspects and certifies the devices used for trade. Navigating these regulatory requirements adds complexity to DWS system implementation, especially for businesses managing high volumes or varying types of products.

1. Certification and Calibration

All measuring devices used for trade must be certified and regularly calibrated to remain compliant. A 2020 study by Measurement Canada found that 22% of devices inspected did not meet the legal standards for accuracy, leading to fines or business disruptions. Regular calibration and certification are necessary to prevent such penalties and ensure continued operations.

2. Complex Regulations

The Weights and Measures Act is highly detailed, covering everything from acceptable error margins to device inspection protocols. According to a 2022 report from the Canadian Federation of Independent Business (CFIB), 30% of Canadian businesses face challenges in navigating these complex regulatory requirements, especially in industries with large-scale or diverse inventories. This complexity makes it essential to ensure that DWS systems comply with all relevant standards.

3. Operational Downtime

Non-compliance with the Weights and Measures Act can result in significant downtime during inspections, recalibration, or replacement of devices. A 2023 report by the Supply Chain Management Association (SCMA) found that downtime resulting from non-compliance can cost warehouses up to $5,000 per hour, depending on the volume of goods processed. This makes proactive compliance and maintenance critical to minimizing disruptions.

How our Right-Sized Partner Packsize Contributes to DWS

Packsize is a global leader in on-demand packaging solutions that helps warehouses optimize packaging operations while working seamlessly with DWS systems. By creating custom-fit boxes tailored to the specific dimensions and weight of each product, Packsize enhances both space utilization and cost-efficiency in shipping.

- Optimized Packaging for Accurate Dimensioning and Weighing

Packsize solutions are designed to work hand-in-hand with DWS systems by producing right-sized packaging based on real-time dimensioning data. A 2022 study by Packaging Digest found that businesses using on-demand packaging reduced void fill by 40%, which significantly lowered shipping costs and improved dimensional accuracy.

By ensuring that packages are no larger than necessary, Packsize reduces wasted space in warehouses and shipping containers, making dimensioning systems more effective. In addition, Packsize helps ensure that weight measurements are accurate, as products are packed with minimal excess materials, eliminating the variability that often comes from oversized boxes.

- Reduced Shipping Costs and Environmental Impact

| Packsize’s ability to create custom-sized boxes based on the exact measurements provided by DWS systems can reduce shipping costs by 10-15%, according to a 2023 report by McKinsey.

Shipping companies like FedEx and UPS charge based on DIM weight (the greater of the package’s volume or weight), and reducing the size of packages directly lowers shipping expenses.

Additionally, reducing the size and weight of packages has a significant environmental benefit. Packsize enables businesses to cut down on packaging waste and shipping emissions, contributing to a greener supply chain.

- Improved Order Accuracy and Efficiency

Using Packsize with integrated DWS systems ensures that packages are correctly sized and labeled, reducing manual intervention and packaging errors. As a result, warehouses can handle high volumes of products with greater speed and accuracy. According to a 2023 LogisticsIQ study, warehouses that implemented automated packaging solutions saw a 25% increase in packing efficiency and a 30% reduction in order errors.

- Compliance with the Weights and Measures Act

By ensuring that packages are right-sized and weighed accurately, Packsize helps businesses stay compliant with the Weights and Measures Act. Systems integrators can calibrate Packsize systems alongside DWS equipment to ensure continuous accuracy and certification by Measurement Canada.

Why Choose a Complete Systems Integrator?

Given the complexity of DWS systems and the regulatory challenges in Canada, working with a complete systems integrator is the best solution for ensuring seamless implementation and ongoing compliance.

1. Expertise in Regulatory Compliance

Systems integrators are experts in navigating complex regulations like the Weights and Measures Act. According to a 2022 survey by Logistics Management, 85% of businesses that worked with systems integrators saw improved regulatory compliance, significantly reducing the risk of fines and penalties. By ensuring that equipment is certified, calibrated, and maintained according to Canadian standards, integrators help warehouses remain compliant without interruptions.

2. Tailored Solutions for Complex Systems

Every warehouse has unique operational needs. A complete systems integrator assesses the specific requirements of a warehouse and designs a solution that maximizes efficiency. According to the 2023 Warehouse Automation Benchmark Report, businesses that implemented tailored DWS systems experienced a 20-25% improvement in operational efficiency within the first year. These customized systems optimize space utilization, improve order accuracy, and reduce shipping costs by ensuring that dimensional and weight data is accurate.

3. End-to-End Project Management

A complete systems integrator manages the entire implementation process, from design and procurement to installation and ongoing support. A 2021 report by Gartner revealed that companies using end-to-end project management for DWS systems saw a 15% reduction in implementation time and fewer operational delays. This allows warehouse operators to focus on their core business without being bogged down by the complexities of integrating new technologies.

4. Cost Efficiency and Future-Proofing

Implementing a fully integrated DWS system leads to long-term cost savings. A 2022 study by Accenture found that businesses using integrated DWS systems reported an average 10-12% reduction in shipping costs due to improved measurement accuracy and fewer manual errors. Moreover, a systems integrator ensures that the system is future-proofed, meaning it can easily adapt to changes in scale or regulations, further reducing the need for costly upgrades in the future.

5. Ongoing Support and Maintenance

Post-implementation support is crucial for maintaining the effectiveness and compliance of DWS systems. According to the 2023 Logistics Trends Report, 78% of companies that worked with systems integrators for ongoing maintenance reported fewer breakdowns and compliance issues compared to those managing the systems independently. Regular maintenance ensures that devices remain accurate and compliant with the Weights and Measures Act, minimizing operational downtime.

Conclusion

The implementation of Dimensioning, Weighing, and Scanning systems is essential for optimizing warehouse operations, but the regulatory landscape in Canada—particularly under the Weights and Measures Act—poses significant challenges. Statistical evidence shows that businesses that adopt advanced DWS systems experience higher operational efficiency, reduced costs, and improved order accuracy. However, navigating the complexities of regulatory compliance and maintaining these systems requires specialized expertise.

A complete systems integrator provides the knowledge and experience necessary to implement and maintain a compliant, efficient, and future-proof DWS system. By offering tailored solutions, managing compliance, and providing ongoing support, Mainway will ensure that businesses can focus on growth while avoiding the costly pitfalls of non-compliance and system inefficiencies. The data supports this: companies that leverage the expertise of systems integrators see fewer regulatory issues, improved operational outcomes, and long-term cost savings, making them the best choice for managing complex warehouse systems in Canada.

Comments are closed