What is the Package

Type?

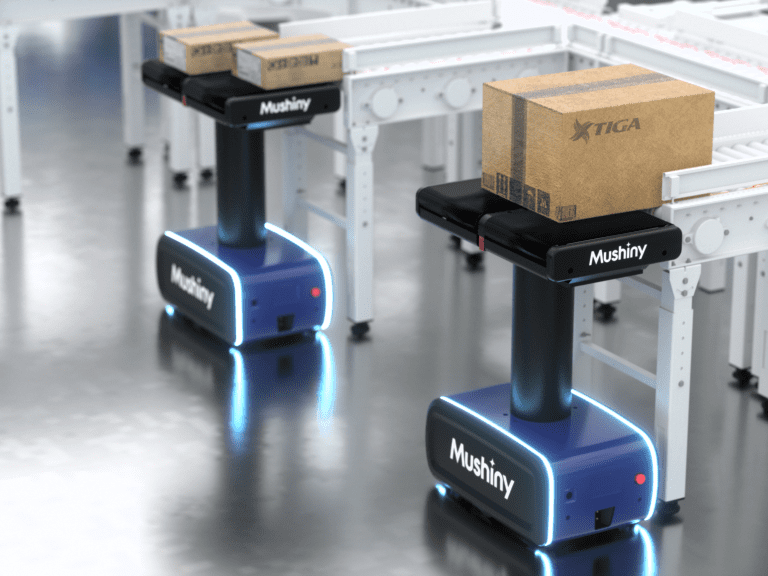

Our state-of-the-art warehouse sortation solutions are designed to revolutionize your distribution center, ensuring seamless order fulfillment, and maximizing operational efficiency.

What is Sortation

Warehouse sortation is the process of systematically organizing and separating items within a distribution center based on specific criteria. This critical step ensures that products are directed to the correct destination, whether it be a specific order, storage location, or shipping area.

Applications of Sortation

Streamline the order fulfillment process by sorting items directly to their designated shipping containers or bins.

Efficiently sort thousands of packages and parcels with speed and accuracy.

Automate the sorting of returned items, expediting the returns processing workflow.

What We Integrate

Rate

Types

Max Pack Size

Weights

Destinations

4000 – 20,000 per hr

Poly, Box

48” x 32” x 32”

1 – 50 kg

15 +

Rate

Types

Min Pack Size

Weights

Destinations

up to 6,000

Poly, Box, Irregular

4” x 4”

0.5 – 50 kg

20+

Rate

Types

Min Pack Sizes

Weights

Destinations

up to 6,000 per hour

Tote, Box

9” x 7” x 3″

1 – 30 kg

5 +

Rate

Types

Max Pack Sizes

Weights

Destinations

up to 10,000 per hr

Poly, Box, Mix Items

up to 60″ x 36″

1 – 45 kg

15 +

Rate

Types

Sizes

Weights

Destinations

3000 – 17,000 per hr

Poly, Box, Single Item

up to 19” x 21.5” x 8”

0.1 – 11 kg

15 +

Rate

Types

Variable Sizes

Weights

Destinations

up to 30 totes per min

Totes, Carton, Box

available

1 – 15 kg

5 +

Rate

Types

Variable Sizes

Weights

Destinations

up to 30 totes per min

Totes, Carton, Box

widths available

1 – 15 kg

5 +

Rate

Types

Max Pack Sizes

Weights

Destinations

up to 2700 totes p/hr

Totes, Trays

17” x 25” x 16”

1 – 30 kg

5 +

Integrating the right technology for your operations is crucial to an efficient & reliable sortation system

How We Integrate

The process begins with the input of data into our sortation system. This can include order information, product details, and destination data. Mainway Handling’s systems are equipped to handle a variety of input sources, ensuring flexibility in integration with your existing systems.

As items move through the distribution center, they undergo scanning and identification processes. This can involve barcodes, RFID tags, or other tracking mechanisms. Mainway Handling’s advanced scanning technology ensures accurate identification of each item in real-time.

Automated conveyors and sorters carry items to their designated locations with precision. This minimizes manual handling, reduces the risk of errors, and increases overall throughput.

Throughout the sortation process, Mainway Handling’s systems provide real-time tracking and reporting. This visibility allows for monitoring the status of items, identifying potential issues, and making data-driven decisions for continuous improvement.

Where we have sorted things out

Benefits

of our sortation solutions

Automated processes and intelligent routing decisions optimize the flow of goods, reducing handling time and increasing throughput.

Mainway Handling’s solutions are designed to be flexible and scalable, adapting to the changing needs of your warehouse.

By ensuring accurate and timely order fulfillment, our sortation systems contribute to enhanced customer satisfaction.

Working with Mainway, the project was completed on time, on schedule and on budget. We have been working with Mainway ever since.

– Steve Vitella, Project Manager for DHL Express