SPS provides high-performance solutions that ensure precise, efficient palletizing, designed to meet the demands of modern warehousing and distribution centers.

Robotic Palletizing Solutions

Savvy Palletizing Solutions is a leading provider of robotic palletizing systems, offering innovative and scalable automation solutions for businesses looking to optimize their palletizing processes. With years of experience in robotics and warehouse automation, SPS is known for delivering durable, reliable systems that can be customized to fit any operational need.

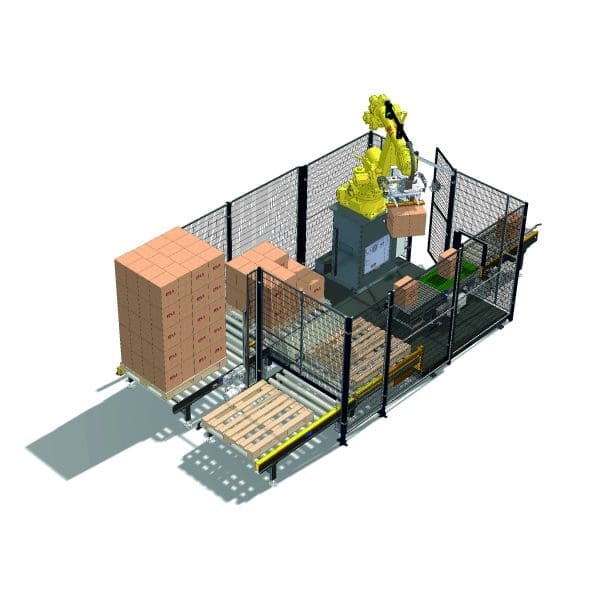

DUOBOT

Rates: Up to 20 cases/min

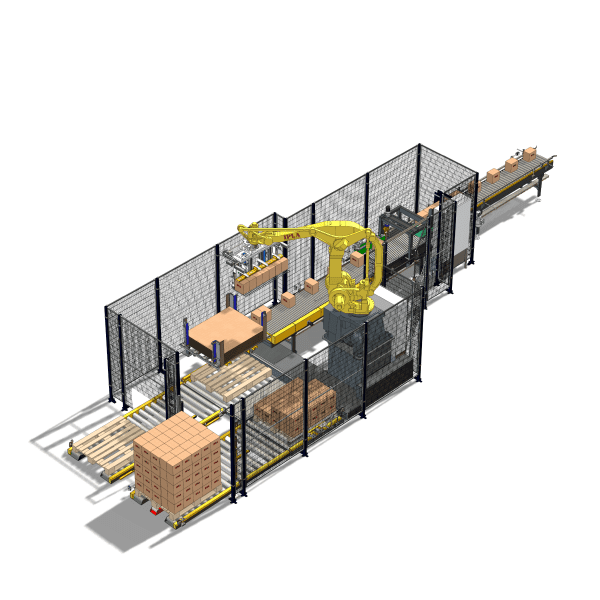

SAVVY PAL

Rates: Up to 30 cases/min

SAVVY PAL XL

Rates: Up to 35 cases/min

Installation & start up in just 3 days

What We Integrate

Industrial strength in just 194 ft2

The new DUOBOT palletizing cell was developed to offer an industrial alternative to collaborative robots. The robot has two palletizing positions that work alternatively. This allows for the operator to access it in order to remove the entire pallet while the robot continues working on the other side.

SAVVY PAL is a unique concept in palletizing. It is mounted on a platform, reducing installation and commissioning time to 3 days. The design is based on versatility, as it can easily work on any type of box between 5”×5” and 24”×16”.

The SAVVY PAL XL is the biggest and fastest solution of the SAVVY Palletizing Solutions family. The gripper is designed to pick up the boxes in rows, allowing it to work with any size and any type of box up to 48”x16”.

optionAL

01

SHEET DISPENSER

Includes the slip sheet deposit and the vacuum device for the gripper.

02

INDUSTRIAL ROUTER

Allows for remote access to the palletizing cell via a WIFI network.

03

FACING

*Only in Match Up configuration

Allows for the final orientation of the boxes to be modified in order to make the label visible or not.

01

PALLET DISPENSER

Allows for feeding in stacks of pallets instead of doing it one at a time. Also includes the security elements.

02

SHEET DISPENSER

Includes the slip sheet deposit and the vacuum device for the gripper.

03

MANUAL FORKLIFT CONVEYORS

Pallet conveyors designed to work with manual forklifts. Distance from floor: 4 in.

04

CUSTOM STAND HEIGHT

*Required if x+y > 95″ in

For loads over 95″ in by adding the height of the highest pallet to the height of the pallet conveyor.

05

INDUSTRIAL ROUTER

Allows for remote access to the palletizing cell via a WIFI network.

06

FACING

*Only in Match Up configuration

Allows for the final orientation of the boxes to be modified in order to make the label visible or not.

01

PALLET DISPENSER

Allows for feeding in stacks of pallets instead of doing it one at a time. Also includes the security elements.

02

SHEET DISPENSER

Includes the slip sheet deposit and the vacuum device for the gripper.

03

MANUAL FORKLIFT CONVEYORS

Pallet conveyors designed to work with manual forklifts. Distance from floor: 4 in.

04

CUSTOM STAND HEIGHT

*Required if x+y > 95″ in

For loads over 95″ in by adding the height of the highest pallet to the height of the pallet conveyor.

05

INDUSTRIAL ROUTER

Allows for remote access to the palletizing cell via a WIFI network.

Whether you’re dealing with fragile products or heavy loads, our bots offer flexibility, speed, and reliability, helping you optimize your end-of-line packaging and shipping operations

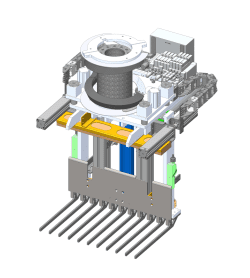

How We Integrate

Savvy Palletizing Solutions robots allow a palletizing speed from 8 to 35 cases/min. In addition, they exclusively use comb-type grippers, which provide a guaranteed 99% OEE. Thanks to their unique features, these grippers are the best choice for a palletizing robot.

Optimal palletizing quality:

Thanks to their built-in reference blade, our grippers ensure perfect palletizing for each box.

Better efficiency:

Our palletizers don’t require mechanical adjustments to change the format of the boxes, so they ensure maximum efficiency.

Greater safety:

There is no chance of boxes breaking during palletizing. Even if the adhesive tape on the B1 cases is poorly applied, cases will not open by themselves during the palletizing process.

ANY TYPE AND SIZE OF PACKAGING

From 5x5x4 in to 24x16x16 in.

One of the biggest problems our customers face is the constant variation in case sizes and formats. With SPS palletizers, we solve this problem by being able to work with any type and size of box from 5x5x4 in to 24x16x16 in.

Installation and start up in just 3 days

Our cells are mounted on a metal platform, which implies an 80% savings on time compared to a conventional robot.

Our palletizers incorporate an integrated pattern generator software. This easy and intuitive software allows you to create a new palletizing pattern in less than two minutes. You can save patterns and switch between them at any time.