Where

Automation

Meets

Innovation

Experience efficiency and precision in every step of your logistics process.

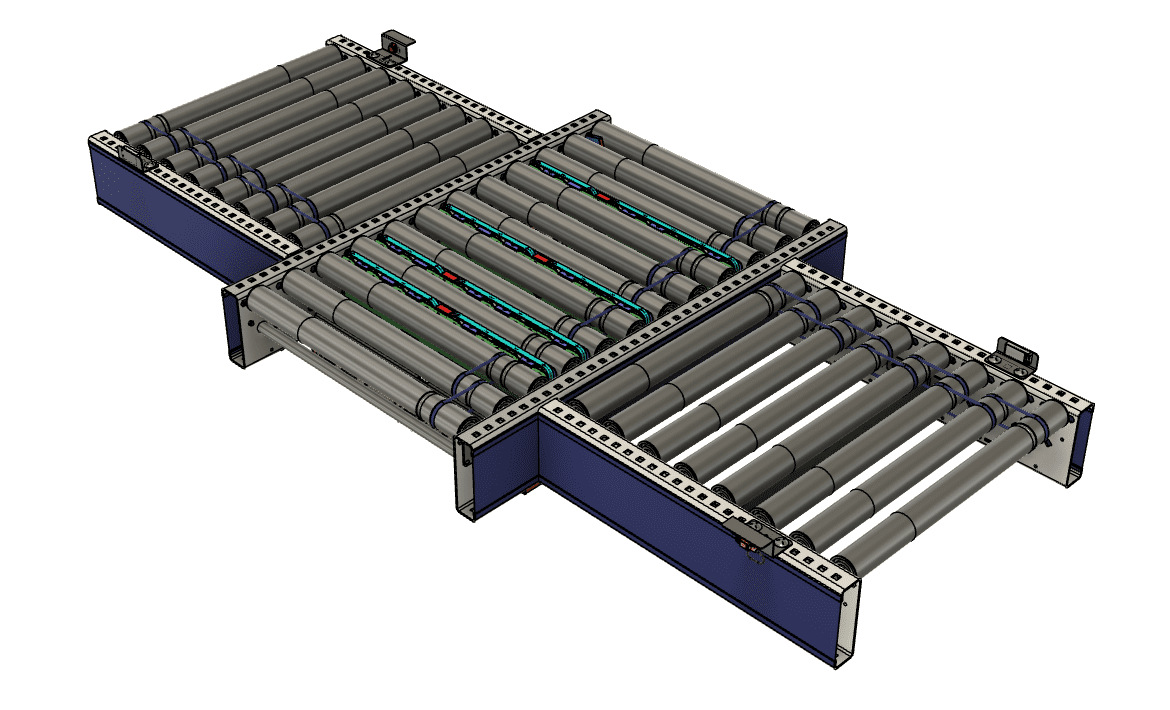

What is motorized Drive roller

Our MDR conveyor features a plug-and-play 24V run-on-demand zones, only running when required to advance product. They can accumulate product without bumping, skewing, or jamming using advanced sensors and controls. Totes, pallets and cartons can be handled simultaneously even when there is a wide difference in weights from one product to the next.

Applications of MDR

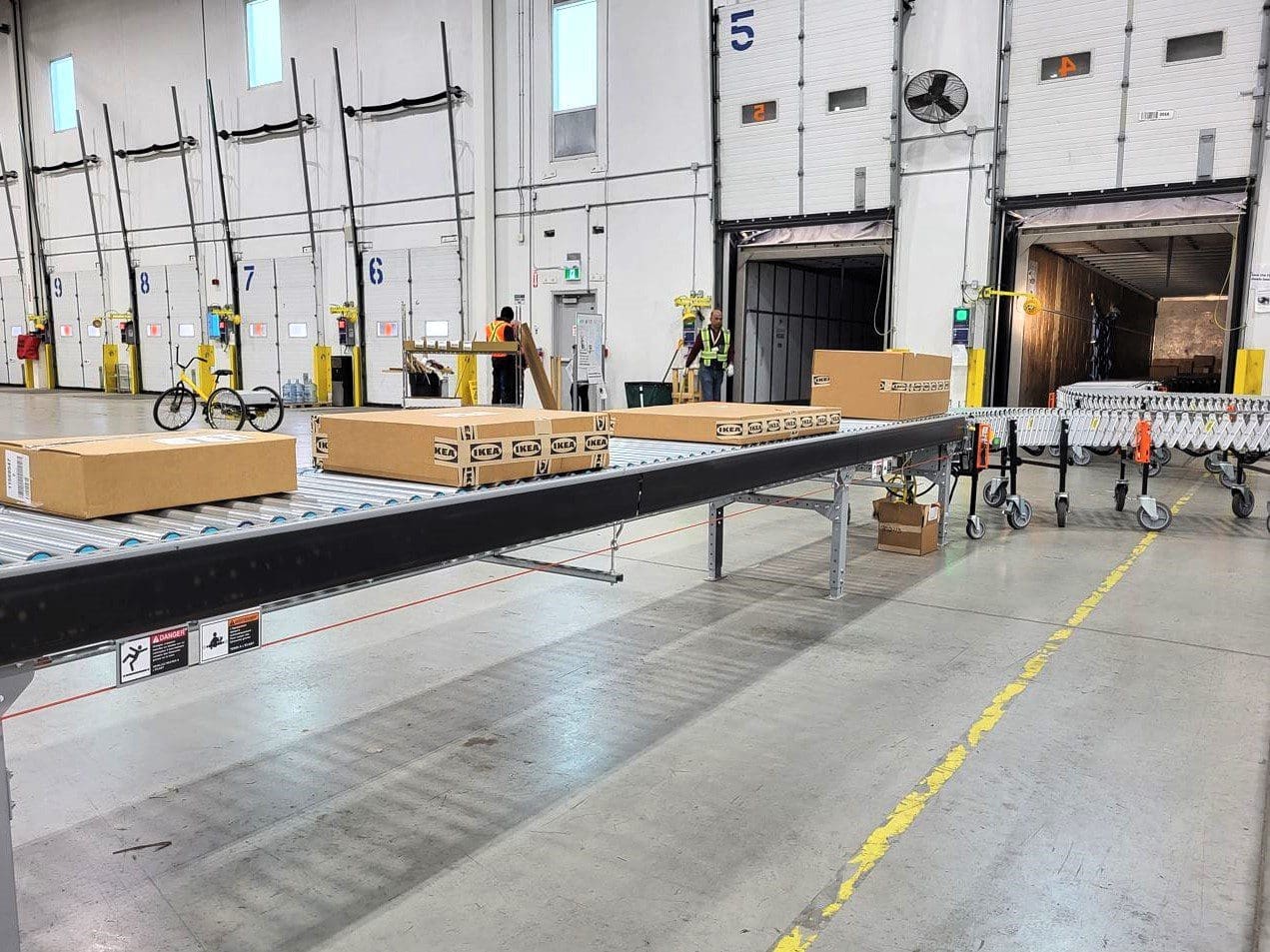

Enhance the movement of orders within fulfillment processes for streamlined production.

Optimize order fulfillment, sorting, and shipping processes in distribution hubs.

Improve the movement of goods within logistics and warehouse facilities for efficient storage and retrieval.

TYPES

straight | curve | DIVERT | POP-UP | MERGE | Decline | INCLINE | BELTED

SPECS

BFR Widths (in)

15½ | 21½ | 27½ | 34½

Zone Lengths (in)

24 | 36

Roller Centers

2″ | 3″ C-C

Roller Coating

- Galvanized Plating

- 2mm Grey Urethane

- Over Roller Belted Zone

Drive Type

- Blue Band O-Ring

- Poly-V w Belting

Sensor Type

- Top Mount Retroreflective Photo Eye

- Undermounted Diffused Sensor

Curve Offering

30° | 45° | 60° | 90°

Junction Offering

- 30° Merge / Divert

- 90° Single and Bi-Directional Transfers

Options

- Dual Motor Zones

- Custom Colours Available

Features

- Floor support and ceiling hangers

- Bolt-on top guard rail

- 3″, 6″, and 12″ high

- Inclines / Declines up to 15°

Live Load Capacity

Up to 75 lbs. per zone

*application specific

Conveyor systems serve as the backbone of modern material handling, our conveyor solutions deliver efficiency, adaptability, and a seamless workflow

Quality Customized

Solution

Future of Warehouse Automation