Warehouses keep goods to be delivered safe and intact. But because of the sheer size and complexity of operations, warehouses can be hard to manage. Efficient workflow is a non-negotiable factor if you want to ensure that all procedures are carried out with minimal time, money, and effort wasted.

But at the rate technology is going today, it’s no surprise that warehouses can be managed better by optimizing processes through sophisticated software. This process is called warehouse optimization, the goal of which is to maintain efficient warehouse operations by planning ways to reduce wasted time, effort, and resources. This process also ensures proper daily warehouse management.

Where Warehouse Optimization Works Best

Thousands, if not millions, of companies around the world are employing warehouse optimization and turning to comprehensive software that can expedite and simplify their processes. Any warehouse servicing any industry can always opt to optimize, but the following industries see warehouse optimization as a must in keeping their houses running smoothly:

1.Healthcare

Medical equipment and medicines have a limited storage time which explains why warehouses needed to store these should have proper and easy management. Materials will surely expire if not stored properly and can threaten human life when used. Audit is required for almost every item, so that’s a lot of paperwork.

2.Food and beverage

Keeping raw ingredients in making food and drinks have to be systematic. Some ingredients tend to spoil easily on the shelf and should be shipped within a limited amount of time.

3.Manufacturing

Any kind of manufacturing business has newly-made and pre-existing goods in their warehouses. It can be challenging to do some inventory if you have too many of these goods stocked up.

4.Retail

The retail industry is one example why warehouse optimization is a huge need. Warehouse optimization helps retailers in keeping an accurate inventory of supplies in every situation, especially high consumer demand.

Why Optimize Your Warehouse?

Every warehouse differs from the other in terms of size, workflow processes, and items being handled. When the work gets too complicated and starts affecting the whole workforce, it’s time to optimize the whole warehouse.

One example of an optimized warehouse is Cardinal Health in the USA. Cardinal Health is an American healthcare service company that once struggled with random work distribution among its employees and product distribution challenges. Using a warehouse management software called AnyLogic, Cardinal Health was able to redistribute workload evenly to its employees and lessen work hours, which resulted in better employee capacity.

If you’re still not convinced, here are some of the reasons to optimize your warehouse:

1.Labour-to-workload match

Optimizing your warehouse allows you to make your employees work with a reasonable workload. You can match the skills of your employees to the workload that you give them. With optimization, the software takes charge of the technical and repetitive tasks while humans can still ensure a smooth workflow throughout the day.

2.Improved planning

When you optimize your warehouse, you can have a more accurate inventory and avoid additional costs for any unexpected circumstance. With the correct and sufficient amount of data, you can allocate resources to keep the operations going smoothly.

3.Increased return customers

Customer satisfaction is a crucial part of any business and you can achieve that by having a properly managed warehouse. The in-demand items are always prioritized and stored extra safely, so you can deliver them to your customers on time. Order fulfillment is one important benefit your warehouse will get with optimization.

4.Efficient tracing of items

Serial numbers are attached to the items and these numbers are logged in the database. Once an item gets lost, the serial numbers are used to identify and retrieve the item. This way of tracing items reduces unnecessary time and effort that can hamper operations.

5.Reduced costs

Operational costs go down by optimizing warehouses. With that, you can allocate money for other expenses that you’ve overlooked before. With reduced costs come extra spaces to store more items in.

The Challenges of Warehouse Optimization

With benefits come challenges, and warehouse optimization is no exception. While you’re painstakingly planning every aspect of optimization, you run into common problems that complicate the whole process. Some of these include:

- Inventory Accuracy

Some companies don’t know the number of items stocked in their warehouse. This is important if you want to have an efficient system in managing inventory. - Inventory Location

It can be hard for pickers to pull out the items to be shipped if they don’t have an idea where a certain item is located. Some of the items don’t have serial numbers to track when needed. - Space utilization and warehouse layout

The more racks and storage systems used the wrong way, the more labour will be needed and more space will be wasted. Inventory will be greatly affected if this situation persists. - Redundant processes

When a process becomes redundant, it adds additional cost to the company and can badly hurt the profit. Unexpected circumstances like wrong purchase orders and damaged items contribute to redundant processes. - Picking optimization

Most warehouses don’t have common routes for picking items to be shipped to the customers. When the manual system fails, the shipment gets delayed and results in customer dissatisfaction. - Fluctuating demand

Not all days are good for the business. When the demand dips, more products sit in the warehouse which occupies a big chunk of space.

Warehouse Optimization: Techniques and Best Practices

Warehouse optimization cannot be achieved overnight. It may take months or years for your warehouse to be fully optimized, but each small step to change your processes and enhance your workflow contributes to a warehouse that runs more smoothly and with fewer errors in the future.

Go all out on optimization and get the full benefits of warehouse optimization by:

1.Planning and automating your processes

Warehouse automation holds the key to making warehouse work easier. The processes that you need to automate are the ones that should have lesser human intervention, like picking, packing, and sorting items. Automating your warehouse management system simplifies the work, collects data faster, and reduces errors that can hamper operations.

2.Taking note of product velocity

Product velocity means how fast products sell in all kinds of seasons. In every warehouse, certain items sell faster than others. Your warehouse inventory management software should enable quick retrieval of best-selling items, so you can easily send them out. Items that sell the most on normal and seasonal days are prioritized.

3.Focusing on warehouse layout design

Take a look at your warehouse design and see the extra spaces you can efficiently use. From there, take an analytical approach when managing the data you need for optimizing the warehouse space. Once you get the proper data, start using the extra spaces in your warehouse the way you see fit.

4.Using warehouse management software

Using software that can help manage the workflow in warehouses is a huge blessing. Workers are juggling picking, sorting, and packing items in a limited amount of time. These items need to be sent to customers without any delay. A management software brings a lot of benefits, such as effective assigning of items to employees, easy item tracking, and reducing labour costs and tasks.

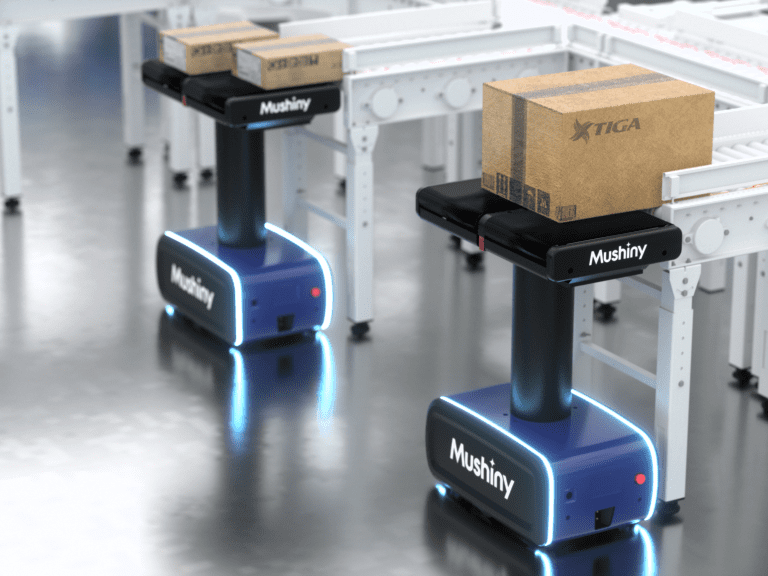

5.Purchasing and investing in robotic equipment

Robotic equipment can cost you a hefty amount of money, but the expenses it can cut for future work are unparalleled. Drones and automated guided vehicles are some of your best options if you plan to buy robotic equipment. There’s so much technology can do these days to help you manage a warehouse. Better capitalize on it now than never.

Optimize Your Warehouse Now

See for yourself the benefits of systems integration for your warehouse in Canada. Mainway Handling Systems delivers leading-edge customizable solutions, with expert service and preventative maintenance programs. We make sure your system runs reliably and efficiently throughout its entire lifecycle.

Email sales@mainwayhandling.com to learn more about what we can do to help you run your warehouse more smoothly!

Comments are closed